forklift lights safety Fundamentals Explained

forklift lights safety Fundamentals Explained

Blog Article

Mechanical malfunctions certainly are a Recurrent cause of forklift mishaps and personal accidents. Challenges like leaky valves and hoses, worn-out or broken tires, and defective brakes can result in mishaps.

What forklift safety lights are necessary by OSHA? Just headlights and taillights? How about blue spotlights or crimson zone LED lights? Regretably, There is not an easy solution.

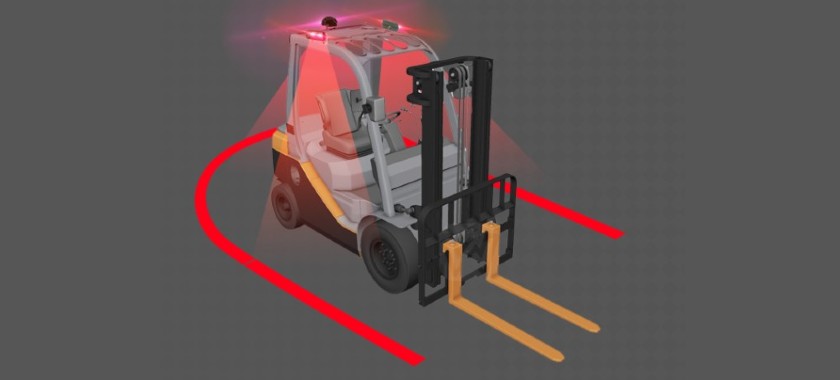

The lights reduce rear-end collisions and foot accidents by building a visible boundary across the forklift. The sturdy design of such safety lights may face up to vibrations and shocks as forklifts are devoid of any standard suspension set up.

Furthermore, pedestrians must talk to with regard to the parts wherever they come to feel the least Secure and voice their tips on how to deal with and improve People worries.

“Jimmy And that i were in a warehouse checking out with a potential customer. That they had Evidently marked aisles, all the proper warning signals, and we were in the correct spot for pedestrians. But we under no circumstances observed warning lights or read the forklift coming just before he blew by us, only about 2 ft away.

By notifying bystanders forklift lights safety and various workers to avoid the forklift's route, this light-weight substantially lessens the risk of incidents and mishaps.

This just ensures that you need to make time to carefully and precisely evaluate your working setting right before choosing what lights really should be put on your forklift.

Drive by using a horn button: The rear-generate cope with provides a secure hand placement to the operator In the carry truck when they need to function in reverse.

The forklift beacon light-weight, generally known as a strobe gentle or warning beacon, is really a highly obvious forklift lights safety flashing mild affixed to your forklift’s roof or other conspicuous areas.

This information aims to demystify the meanings and symbols in the forklift instrument panel's forklift lights safety 24 commonest warning lights. By giving an in forklift lights safety depth overview, we seek out to reinforce knowledge and promote a safer Operating natural environment for all linked to forklift operations.

Visible inspection: Operators should really forklift lights safety inspect the forklift for any visible indications of injury, for instance leaks or worn-out tires.

To be certain top safety, forklifts will need to be straightforward to recognise. Forklift operators should have the ability to see Obviously. Possessing mentioned that, it’s why forklift safety lights are Definitely critical.

Flooring markings could be a perfect safety navigation. OSHA standards emphasize the necessity of marking lasting aisles and passageways.

A single crucial way to avoid accidents is to utilize forklift lights appropriately. Learn how forklift accidents manifest And just how very simple warning lights can decrease mishaps During this tutorial to forklift safety lighting.